PATTERN MAKING

Pattern making is a process of translating the engineering drawings into foundry tooling so that an accurate casting is made out of it. Patterns are full-size models of the finished casting. This is the basic process of product development. We can work with a variety of materials including:

Aluminium

Wood

Cast Iron

Araldite

In addition, our CNC machining capabilities allow us to create complex, detailed, and highly accurate patterns with both small and large size.

In Muthu pattern works, we make foundry and casting patterns to your exact specifications. We are dedicated to producing highly accurate and specific design patterns, as we know our finished form corresponds directly to the shape desired for casting. We understand the importance of creating models set to exact design specifications, which allows us to exceed your expectations and to fulfill your requirements with 100% satisfaction

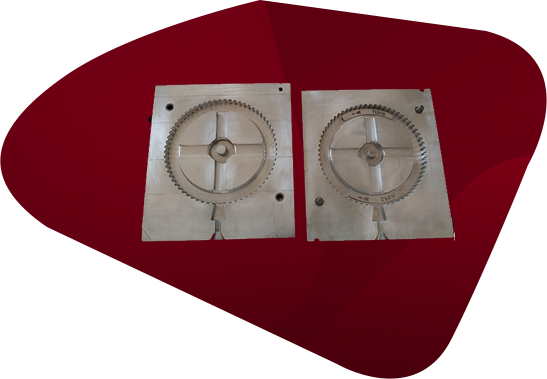

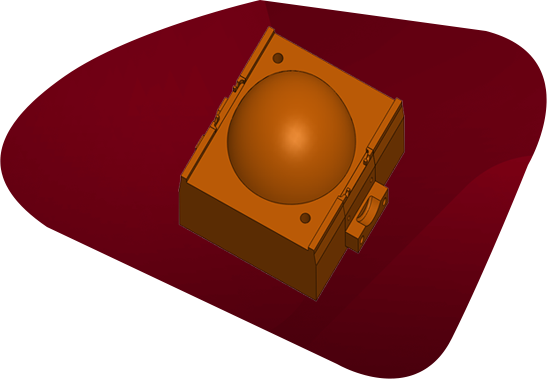

Machine Moulding Patterns

The patterns are made up of aluminium or either Cast iron (as integrated) are usually mounted with the CI Match plate. These type of patterns are suitable for machine moulded green sand casting process.

Possible no.of cavities in the mould is limited to the weight & size of the casting depend on the moulding machine.

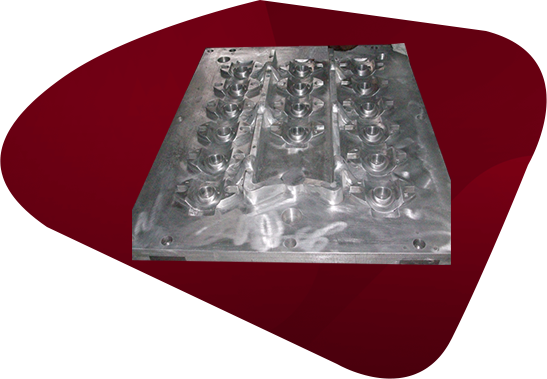

Hand Moulding Patterns

Large size of components cannot be accommodated in machine moulding process. So it is brought to hand moulding processes like furan sand casting, No bake moulding or Co2 Moulding process where the match plate size can be customized according to the size of the component and Mould box. Here wooden match plate is used for ease of handling.

Wooden Patterns

Wooden patterns are done for the short term of production and R&D Purposes. It is mostly made of Teak wood for more life and durability comparatively.

Shell Moulding Patterns

These patterns are made up of S.G Iron, where it is heated up to particular temperature to form a shell like sand.

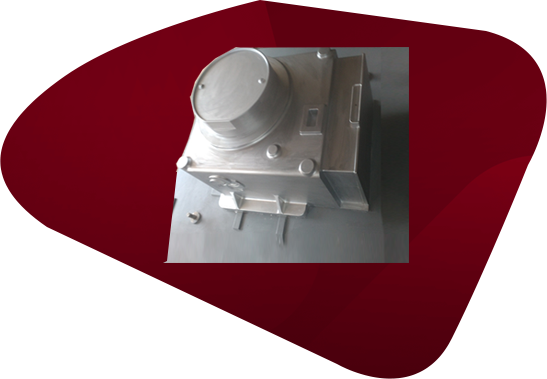

Gravity Dies

These dies are made up of S.G Iron, with close tolerance to the component. Through gravitational force, the molten metal fills the die cavity with the good surface finish.

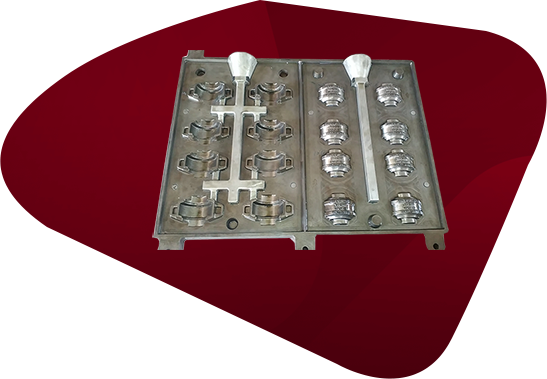

Investment Casting Dies

Here the dies are mostly made up of Aluminium to get the wax pattern, which is same as the final component.